FAQ: What is Hydrogen Embrittlement?

By Engaged Expert

Vikram N和aWith over 20 years of experience, Vikram leads a team of failure analysts 和 metallurgists, 为im体育APP公司阿联酋地区的冶金失效调查提供技术支持和专家意见.

We asked our metallurgy 和 failure analysis expert Vikram N和a 来回答他和他的团队每天收到的关于氢脆的常见问题. Read his answers below to discover the causes, effects, prevention of hydrogen embrittlement, 和 much more.

What is hydrogen embrittlement (HE)?

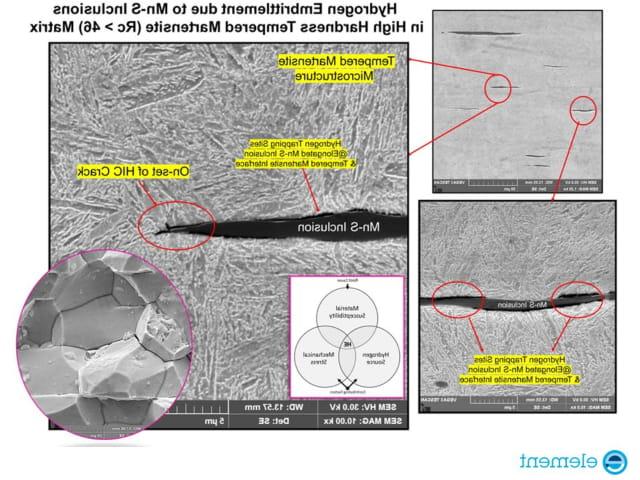

氢脆(HE)的特点是由于金属吸收氢原子而导致延展性和强度的损失, which eventually diffuses along the grain boundaries, weakens the material structure, 和 promotes Intergranular Cracking. As the metal strength increases, steel becomes harder, less ductile, less tough, 和 becomes more susceptible to HE. 氢脆的结果是钢构件在低于金属屈服强度的应力下以脆性形态开裂和断裂.

What is hydrogen embrittlement in steel/stainless steel?

氢脆主要发生在高强度钢中, 而不锈钢被认为相对不易受氢脆的影响,但并非完全不受HE的影响. 氢脆本质上是由于在制造过程中氢原子被金属吸收而导致的延展性的丧失和承载能力的降低, fabrication, or in service. Hydrogen atoms are small 和 can easily permeate solid metals.

Once absorbed, 原子氢在各种俘获位点(如空隙/包涵位点或材料内部缺陷)重组,形成氢分子(H2)。, which create pressure from within the metal. 这种压力可以增加到裂纹产生的水平,并最终降低这些裂纹在金属中传播所需的应力, resulting in embrittlement (brittle fracture).

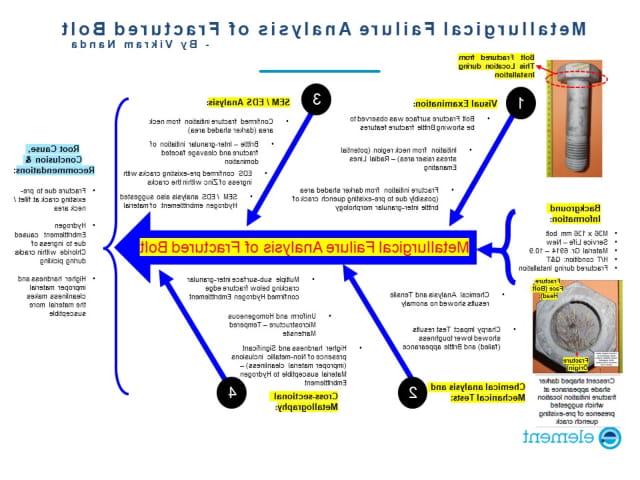

How does hydrogen embrittlement happen in bolts?

性能等级为10的高强度钢螺栓的氢脆(HE).9 & 12.众所周知,9的发生主要是由于氢原子改变了物质的行为. As a result, 这可能导致在拉紧过程或在使用条件下的拉伸载荷下的脆性断裂.

What is hydrogen embrittlement temperature?

氢脆(HE)是一种接近环境温度的现象. 当温度高于100℃时,HE逐渐减小.

What causes hydrogen embrittlement?

氢脆是由氢原子被吸收到微观结构中具有氢捕获点的材料中引起的. 这可能导致在施加应力或残余应力下延展性和韧性的丧失,并在低于金属屈服强度的应力水平下促进开裂和脆性断裂. The source of hydrogen atoms could be corrosion reactions, electroplating processes, acid pickling, 或者使用潮湿的焊条进行焊接等制造过程. In general, high-strength materials are more susceptible to HE.

“氢脆的最大挑战是很难检测和预测. 随着时间的推移,氢脆的过程可能会缓慢发生,直到部件发生灾难性故障时才会立即显现出来. ”

Vikram N和a

Metallurgy & metallurgical failure analysis expert

如何防止电镀紧固件发生氢脆?

防止氢脆最常见的方法之一是通过一个叫做烘烤的过程. 烘烤通常包括将电镀紧固件加热到指定温度,并将其保持在~180 - ~220ºC的温度下,持续8至24小时.

Which metal is the most vulnerable to hydrogen embrittlement?

氢脆(HE)对所有金属材料的影响并不相同. 最脆弱的材料是高强度的钢(如那些使用在 aerospace 和 automotive industries), 还有钛和钴合金,而其他材料,比如铜, aluminum, stainless steels, 和 some nickel alloys, have relatively low susceptibility to HE. 然而, 如果这些材料经历了应变硬化过程, then they may get affected by hydrogen embrittlement.

镀铬、镀锌、化学镀镍也可能引起HE. 值得注意的是,材料对氢脆的脆弱性可能受到多种因素的影响, such as the presence of impurities in the material, 在制造/制造或服务过程中氢气暴露的水平, stress level (applied 和/or residual), 以及它被使用的温度和压力条件.

How do you identify hydrogen embrittlement?

识别氢脆裂纹最有效的检测方法是 magnetic particle testing (MPT) 和 ultrasonic testing (UT). MPT is particularly useful for identifying surface cracks, 然而, from my experience, implementing MPT on small fasteners, could be a challenge.

How can im体育APP help?

英国,美国和中东的im体育APP实验室可以执行机械 hydrogen embrittlement testing according to ASTM F519. 测试规范概述了持续载荷测试(SLT)的使用,通过施加长达200小时的单轴拉伸来测量钢材料中氢脆的可能性.

Contact us 了解更多im体育APP如何进行氢脆测试.

Find related Resources

“进行氢脆测试的最大好处是,它有助于确保受到高应力和暴露于氢的关键部件的安全性和可靠性, such as those used in the aerospace, automotive, 和 energy industries. ”

Vikram N和a

METALLURGY & METALLURGICAL FAILURE ANALYSIS EXPERT

Releted Services

Hydrogen Embrittlement Testing

im体育APP执行符合ASTM F591的氢脆(HE)测试, 电致氢应力开裂(GHSC)符合NACE MR0175/ISO 15156和氢致应力开裂(HISC)测试.

Ultrasonic Testing (UT) & Inspection Services

超声波检测(UT)是一种利用声波检测零件和材料的裂纹和缺陷的无损检测方法. It can also be used to determine a material’s thickness, such as measuring the wall thickness of a pipe.

Magnetic Particle Inspection

Find out more about magnetic particle inspection, sometimes called MT, MPI, or mag particle, 一种无损检测方法,用于检查表面和表面下的不连续性和缺陷.